Manufacturing 4.0

The 4th Industrial Revolution

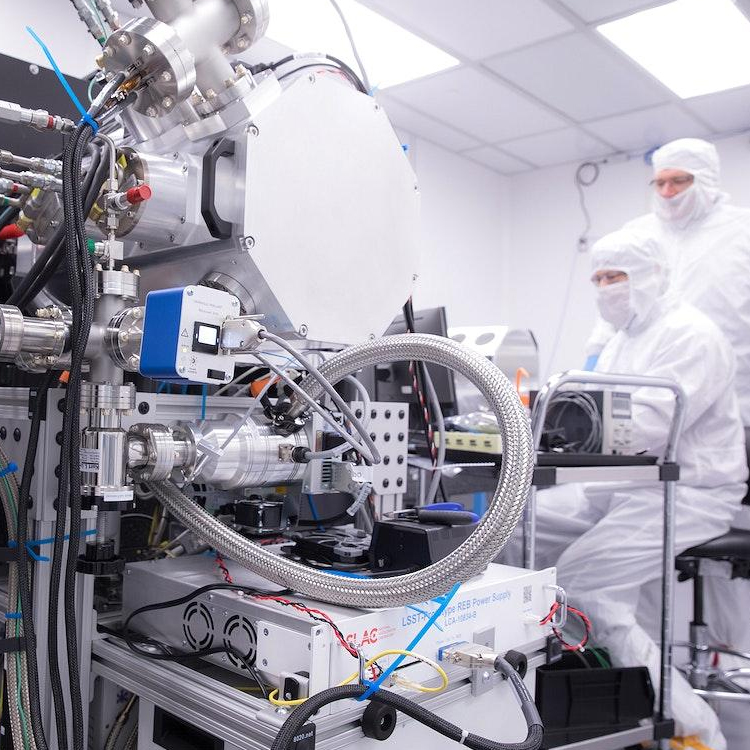

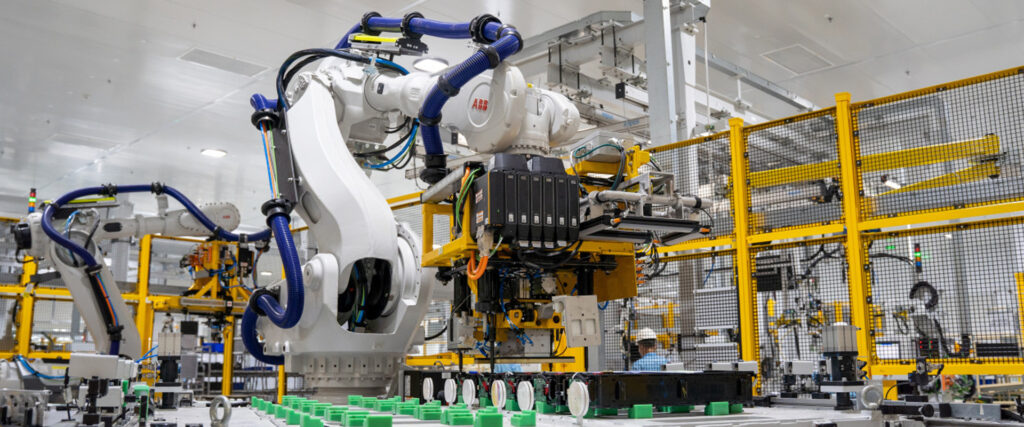

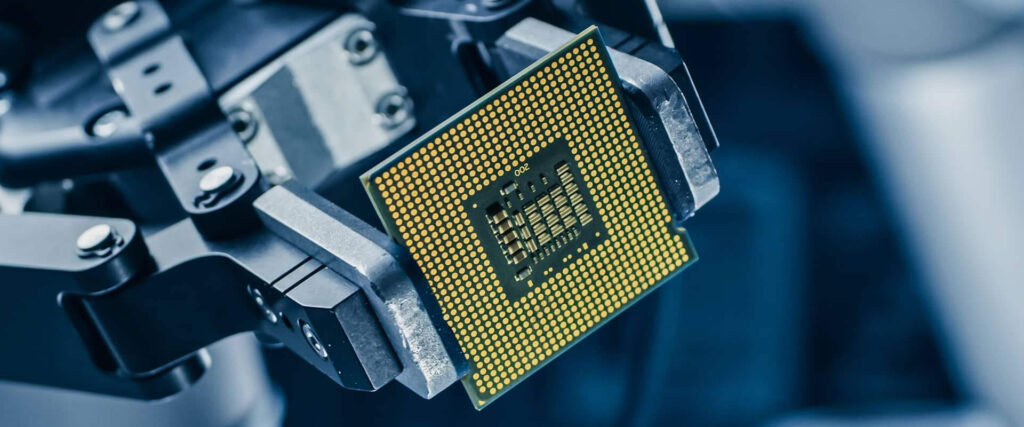

The SMART Giga Micro Factory combines the principles of Manufacturing 4.0 with the concept of a micro factory to create a groundbreaking production environment. It leverages advanced digital technologies, automation, and connectivity to optimize manufacturing processes and achieve maximum efficiency. The Giga Micro Factory embraces the Fourth Industrial Revolution by integrating artificial intelligence, Internet of Things, big data analytics, and robotics into its operations.

At its core, the SMART Giga Micro Factory aims to revolutionize traditional manufacturing practices by enabling real-time data exchange, predictive analytics, and intelligent decision-making. By interconnecting machines, devices, and systems, it creates a networked ecosystem that streamlines operations, enhances productivity, and reduces costs. This digital integration enables seamless communication, monitoring, and control of the production process, resulting in improved quality control, reduced downtime, and increased flexibility.

Through the adoption of robotics and automation, the Giga Micro Factory optimizes repetitive tasks and facilitates human-robot collaboration to achieve higher productivity levels. Additionally, it employs AI algorithms to analyze vast amounts of data, enabling predictive maintenance, optimizing resource allocation, and driving continuous process improvement.