sustainability

recycle

SUSTAINABILITY

Recycle | reduce | recover

RECYCLE

REDUCE

RECOVER

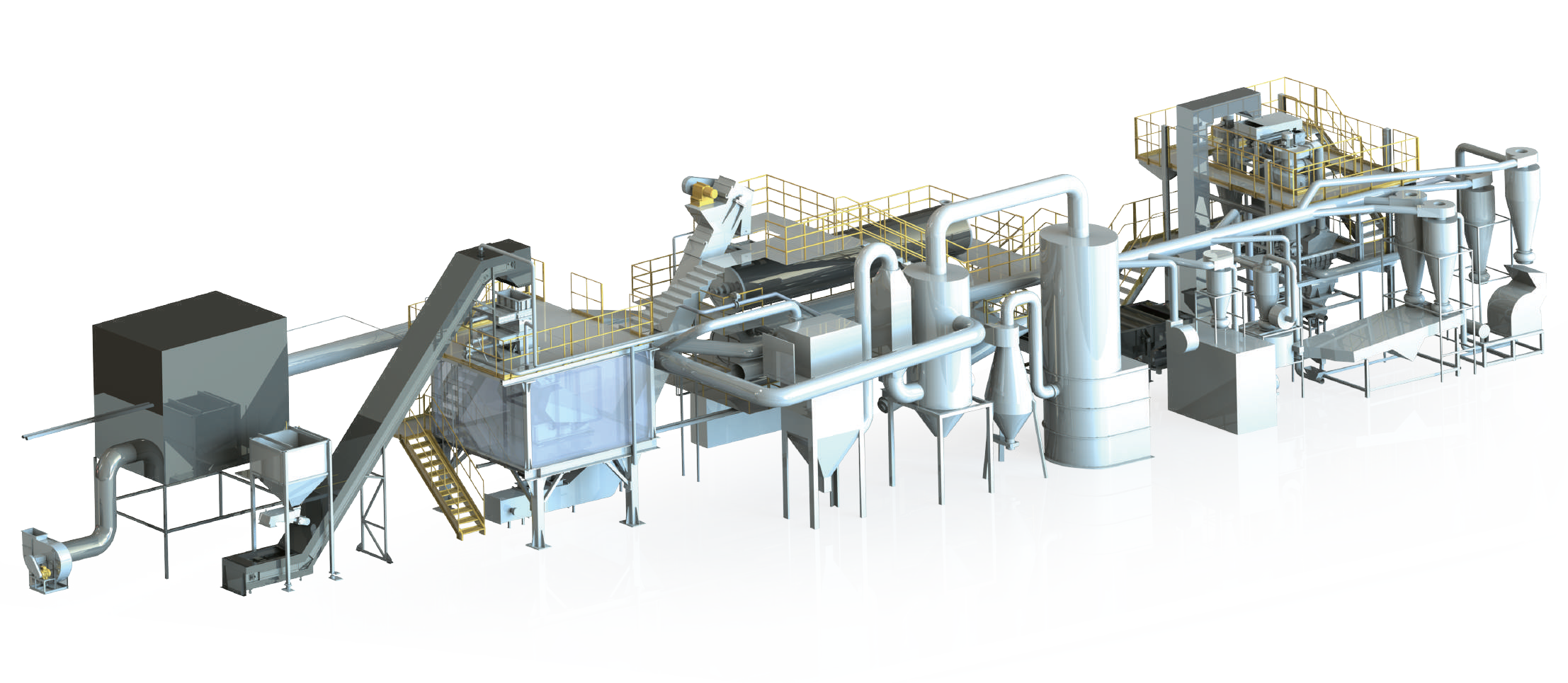

State of the art battery recycling & recovery system

Recycling lithium-ion batteries not only conserves resources but also minimizes the environmental impact of hazardous materials. It is a crucial step in promoting sustainable practices within the rapidly growing electric vehicle and electronic device industries.

RECYCLING & MANAGMENT

oUR pROCESS

Pre-processing

A recycling plant typically includes a sorting stage to separate different types of lithium-ion batteries based on size, chemistry, and voltage.

Battery Discharge

Before further processing, discharged batteries are often subjected to a discharge process to ensure safe handling and minimize potential risks associated with stored energy.

Size Reduction

Before further processing, discharged batteries are often subjected to a discharge process to ensure safe handling and minimize potential risks associated with stored energy.

ElectrocheM Processing

Some advanced recycling methods employ electrochemical processes, such as electrodeposition or electro-winning, to selectively recover specific metals from solution and regenerate usable materials.

Pyrometallurgy

Thermal treatments, including smelting or roasting, may be employed to recover metals from the battery materials. These high-temperature processes allow for the separation and extraction of valuable metals through various refining techniques.

Recovery and Refining

Post chemical processes, the resulting solutions or compounds undergo further refining and purification to obtain high-purity metals suitable for reuse in battery production or other industries.

Hazardous Waste Management

Batteries contain hazardous materials, and proper waste management is essential. Recycling plants should have robust systems to handle and treat hazardous waste generated during the recycling process, ensuring compliance with environmental regulations.

Emission Control Systems

Recycling plants incorporate advanced emission control technologies, such as scrubbers, filters, and air purification systems, to minimize the release of pollutants and ensure a safe working environment for employees.

Quality Control and Testing

Throughout the recycling process, quality control measures are implemented to ensure the purity and quality of the recovered materials. Various testing methods, including chemical analysis and material characterization, are used to assess the composition and suitability of the recycled materials for reuse.

RECYCLING REDUCE RECOVER

salient features

Capacity

The plant will have a maximum throughput capacity of 10,000 batteries per day, accommodating various types such as lead-acid, lithium-ion, and nickel-metal hydride batteries.

Battery Types

Lead-acid batteries from automotive, industrial, and commercial sectors, as well as lithium-ion batteries from portable electronic devices and electric vehicles, are processed.

Processing Equipment

The plant is equipped with state-of-the-art machinery including battery disassembly lines, shredders, separators, smelters, and chemical treatment reactors.

Environmental Controls

Emission control systems will include HEPA filters and scrubbers to capture particulate matter and neutralize acid gases. Wastewater treatment systems will utilize sedimentation tanks, filtration, and chemical precipitation to remove contaminants.

Safety Protocols

All personnel undergo comprehensive safety training and will be provided with appropriate PPE, including gloves, goggles, and respirators. Emergency response plans are in place for spills, fires, and other potential incidents.

Quality Assurance

Regular sampling and analysis are conducted to ensure the purity of recovered materials, with testing performed for lead, lithium, cobalt, nickel, and other valuable metals. The plant will adhere to ISO 9001 and ISO 14001 standards.

Resource Recovery

Recovered materials will undergo refining processes to achieve high purity levels suitable for resale or reuse in manufacturing applications. Efforts will be made to maximize recovery rates for all valuable materials.

Compliance

The plant will comply with all relevant regulations, including EPA guidelines for hazardous waste management, OSHA standards for occupational health and safety, and local permitting requirements.

Community Engagement

The plant will engage with local communities through outreach programs, public meetings, and educational initiatives to promote awareness of battery recycling practices and address concerns related to environmental impact and safety.

Business Inquiry

recycling & recovery

Subscribe to our newsletter to hear the latest news on Recycling Batteries.